Proline – Relining of Sewers

& ventilation

Market leader in relining

Proline Group is a turnkey supplier of pipe renovation for systems within storm water and waste water as well as ventilation. We solve your specific needs in a convenient, cost-effective and environmentally friendly manner. And you can be completely assured of the quality of the work carried out.

Old pipes become like new (inside).

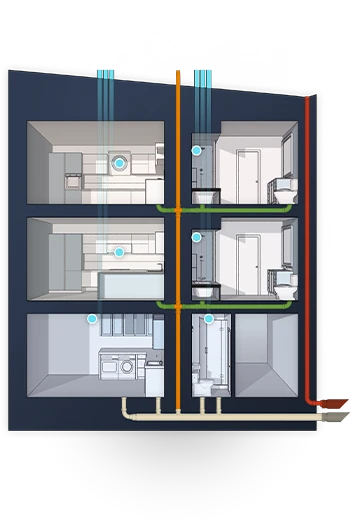

Relining is a collective term for renewing old and worn pipelines. Traditionally, piping systems have been renovated by replacing pipes and wires with new ones. With relining, old pipes can be renewed without having to tear out existing pipes. This means significantly lower costs, minimal waste, minimal disturbances for the residents and a significantly faster work process.

With relining, all or parts of the system can be renovated as is

- Stormwater trunks

- Waste water trunks

- Apartments

- Collection lines

- Basement pipes

- Service lines

Relining is also called pipe renovation, pipe lining, lining, trunk renovation, trunk line renovation, flexible liners, interior coating and pipe-in-pipe.

This is how the process works.

The work follows a flow consisting of six different points. Here you can take part in them, and learn more about our methods.

1. Information

First we inform all the relevant parties about what we will do, the schedule and milestones. Obviously we answer any questions. All information to the residents is first anchored at the client.

2. Cleaning

We lay out protective paper on the surfaces we are working on, after which bathroom fixtures and water traps in the apartment are dismantled. Through inspection hatches, floor drains or connections to the toilet and washbasin we thoroughly clean with water and a rotating cleaning tool. After that the pipe is dried. Residents can remain in their apartment during the course of the work. They don’t even need to move furniture aside or cover it to protect them against dust.

3. Inspection

Using a camera we conduct a thorough examination of the whole sewage and drainage system where everything is inspected. Each deviation is documented in an inspection plan. If the pipe needs to be mended we have our own technique for repairs.

4. Renovation / Relining

We use two different methods for the renovation of old pipes. Which one is best suited varies between different assignments. In some projects, a combination of both methods is the best solution.

1 – THE POLYESTER METHOD.

The old pipes are renovated with polyester plastic in several layers with an hour of curing in between. Our coating gets a material thickness of about 3 mm.

2 – FLEXIBLE LINING.

We twist in a flexible lining. Lining is put under pressure and hardened. Plug lines and manifolds are opened with an internally working robot that mills the manifold opening to full flow. Finally, the custom-made crotch reinforcement is fitted.

5. Control & Documentation

When the relining is finished the quality of the relining carried out is inspected using a camera. All pipes are documented with traceability on film. Then bathroom fixtures and water traps are refitted in the apartment. And you will hardly notice that we have been there.

6. Handover

Finally, documentation is handed over to the client. All material documented on film is submitted together with a signed inspection plan of all pipes to the property owner/client, in connection with approval of the renovated pipe system. Documentation consists of a warranty and is very useful in the event of any need of future work on the piping system.